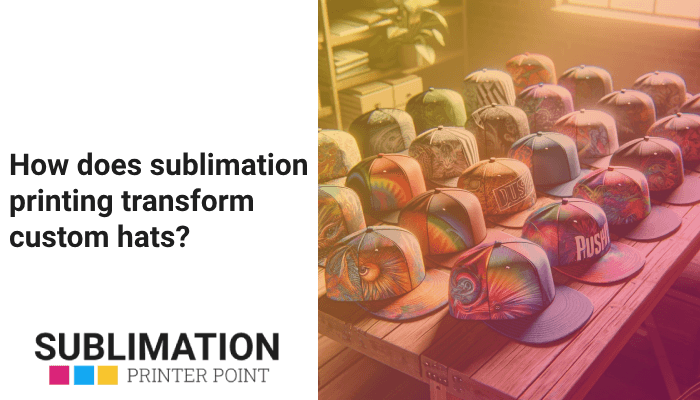

Sublimation printing on hats is an increasingly popular solution that is gaining a growing number of supporters. The technique, which uses a combination of specialized materials, heat transfer and sublimation ink, creates durable prints, revolutionizing the market.

Hat sublimation printing is a transformative process that eschews the liquid phase by using heat to convert sublimation ink from a solid to a gas. This method produces bright, long-lasting graphics on caps made of polyester or a combination of polyester. A heat press, sublimation paper, ink, and a sublimation printer are among the specialized equipment needed for the procedure. The finished result is greatly influenced by the caliber of these materials. Because of the growing need for customized clothing, sublimation printing presents a profitable business potential despite the learning curve and early expenditure.

- Sublimation printing uses heat to transform sublimation ink directly from a solid to a gas, creating vibrant designs on hats.

- The process requires specific tools, including a sublimation printer, sublimation ink, sublimation paper, and a heat press.

- The quality of the sublimation materials plays a crucial role in the final product.

- Despite the learning curve and initial investment, sublimation printing offers a lucrative business opportunity due to the rising demand for personalized apparel.

| Sublimation Component | Description | Role in Sublimation |

|---|---|---|

| Sublimation Ink | A unique concoction containing special dyes suspended in a liquid carrier. | Responsible for the vibrant colors seen in sublimated products. When subjected to high temperatures, these dyes vaporize and permeate the fabric, creating a permanent bond. |

| Heat Transfer | The process of applying heat and pressure to the sublimation paper. | Triggers the transformation of the sublimation ink from a solid to a gaseous state, allowing it to permeate the fabric. |

| Sublimation Paper | The canvas onto which the design is initially printed using sublimation ink. | When placed against the fabric and subjected to heat and pressure, it releases the ink, allowing it to permeate the fabric. |

| Heat Press | A tool designed to apply both heat and pressure to the sublimation paper. | Triggers the transformation of the ink into a gas, allowing it to permeate the fabric of the hat, resulting in a vibrant, durable print. |

The main elements, their descriptions, and their functions during the sublimation process are listed in this table.

What is the science behind sublimation printing?

A intriguing scientific idea forms the basis of the groundbreaking method known as sublimation printing. Sublimation is the process by which a substance goes straight from a solid to a gaseous state without first passing through a liquid phase. Heat and pressure are used to bring about this transformation. When heated, the sublimation ink changes into a gas that seeps into the cloth and freezes into the fibers. The end effect is a vivid, long-lasting color that doesn’t fade even after several washings. Gaining expertise in the art of sublimation printing on hats—a prominent trend in the bespoke garment industry—requires an understanding of this science.

What are the key components of sublimation ink?

The key ingredient in the sublimation process, sublimation ink, is a special mixture. It has unique dyes in a liquid carrier suspended in it. These dyes are the main actors since they give sublimated items their vivid hues. These colors evaporate and penetrate the fabric at high temperatures, forging an irreversible connection. For those attempting to DIY sublimate on caps, the quality of the sublimation ink is crucial since it has a significant impact on how the sublimation process turns out.

How does heat transfer work in the sublimation process?

Heat plays an essential function in the sublimation process. The catalyst is what causes the sublimation ink to change from a solid to a gaseous state. A heat press aids in this procedure, which is referred to as heat transmission. The sublimation paper is subjected to pressure and heat from the heat press, which causes the ink to evaporate and seep into the cloth. The unique, durable prints on sublimated hats are a result of this heat-induced metamorphosis.

Did you know that the brilliance and longevity of your prints are greatly impacted by the quality of your sublimation ink? Purchasing premium ink can have a significant impact on your custom sublimated hats. Additionally, keep in mind that polyester or blend textiles are the ideal choice for sublimation printing. Making use of these supplies can guarantee that your designs are vivid and durable.

What role does sublimation paper play in the process?

In the sublimation process, sublimation paper acts as a mediator. It is the canvas that is first printed with the design using sublimation ink. The ink is released from this paper and is able to seep into the cloth when it is pressed up against the fabric and heated. A key step in the sublimation process of headwear is the quality of the sublimation paper, which has a substantial impact on the final print’s clarity and vibrancy.

How is sublimation printing applied to custom hats?

Custom hats have undergone a revolution because to sublimation printing, which provides countless customization options. The first step in the process is creating a design, which is then printed using sublimation ink onto sublimation paper. After that, the paper is put on the hat, and the design is transferred using a heat press. The heat produces a vivid, long-lasting print by vaporizing the ink and allowing it to penetrate the hat’s fabric. This method is very well-liked for making personalized sublimated headwear since it can produce elaborate patterns and a broad range of colors.

What types of hats are suitable for sublimation printing?

Hats of all shapes and sizes can be printed on using the flexible sublimation printing technology. But it works best on hats composed of polyester or blends of polyester. This is so that the heat transfer process creates a strong, brilliant print by bonding the sublimation ink with the polyester fibers. Natural fiber hats, such as cotton ones, are less suited for sublimation since the ink does not adhere to them as well, resulting in less vivid colors and a print that could smudge over time.

How does a heat press work with hats?

Particularly for hats, a heat press is a necessary equipment in the sublimation process. Its purpose is to cause the ink to turn into a gas by applying pressure and heat to the sublimation paper. Heat presses designed specifically for hats include a curved platen that conforms to the shape of the hat and ensures a uniform transfer of the pattern. It is a flexible instrument for do-it-yourself sublimation on caps because the temperature and pressure settings of the heat press can be changed to meet the unique needs of the hat and the sublimation ink.

If you’re unfamiliar with sublimation printing, don’t be scared to look for guides and resources. Websites such as CreativeFabrica.com, Sepsgraphics.com, and YouTube provide a plethora of resources to assist you in getting started. In addition, think about participating in internet forums where sublimation aficionados gather to exchange advice and benefit from one another’s experiences.

What are the steps to apply a sublimation design on a hat?

There are several procedures involved in putting a sublimation design on a hat. Sublimation ink is first used to produce the design, which is then printed onto sublimation paper. After that, the paper is put onto the hat, and the design is transferred using a heat press. The heat produces a vivid, long-lasting print by vaporizing the ink and allowing it to penetrate the hat’s fabric. After that, the hat is left to cool before being worn. This method, called the cap sublimation decoration technique, is well-liked by both companies and do-it-yourselfers because it offers a great deal of personalization.

What equipment is needed for sublimation on hats?

Before you start hat sublimation, there are a few things you need have. The main instruments required to make the design are a sublimation printer, sublimation ink, and sublimation paper. The design is applied to the hat using a heat press made especially for headwear. To generate and modify designs, a computer equipped with design software is also required. Lastly, in order for the sublimation ink to properly adhere to the fabric, hats composed of polyester or a polyester blend are necessary.

What are the features of dye-sublimation printers for hats?

One essential component of the sublimation process are dye-sublimation printers. The usage of sublimation ink, which is essential to the heat transfer process, is built into these printers. Their ability to print complex patterns in an extensive color palette makes them perfect for producing personalized sublimated headwear. For even more control over the result, some advanced models come equipped with capabilities like print preview and color adjustment. Considerations including print quality, speed, and ink efficiency should be examined while choosing a dye-sublimation printer for hats.

What are the different types of heat presses for hats?

Hat heat presses are available in a variety of sizes and forms, each with special characteristics. Because of their hinged shape and ease of use, clamshell heat presses are a popular option for novices and small enterprises. They also take up less space. More accurate and uniform pressure distribution are features that swing-away heat presses provide, which makes them perfect for intricate designs. Cap heat presses use a bent platen to conform to the shape of the cap; these presses are specifically made for hats. The volume and complexity of the sublimation projects being worked on have a major influence on the heat press selection.

What are sublimation blanks and how are they used?

Items that have been pre-treated to accept sublimation ink are known as sublimation blanks. These would be hats composed of polyester or a blend of polyester that are prepared for sublimation printing customization in the context of hat sublimation. The sublimation paper and these blanks are put in the heat press, and the heat transfer process is started. Because sublimation blanks are made especially to operate with sublimation ink, using them makes the process easier and guarantees the best results.

What are the benefits and challenges of sublimation on hats?

Among the many advantages of sublimation on hats are vivid, long-lasting prints and a high level of personalization. It is a popular option for personalized hats since it permits complex designs and a broad range of colors. It does, however, also come with certain difficulties. There is a learning curve to become proficient with the procedure, and certain tools and materials are needed. Moreover, only polyester or blend materials work best for sublimation, which restricts the kinds of hats that can be utilized.

What makes sublimation printing a popular choice for custom hats?

Because sublimation printing offers so many benefits, it has become more and more popular in the custom hat industry. It permits extensive customisation, allowing for a broad range of colors and complex designs. Even after several washings, the prints retain their color and brightness. In addition, the procedure may be completed internally and is reasonably simple, which makes it a popular option for both enterprises and do-it-yourselfers. Customers find sublimation printing to be quite appealing since it allows them to create individual, personalized headwear, which makes it a profitable business.

What are the potential issues with sublimation on polyester hats?

Although sublimation on polyester hats has many advantages, there are drawbacks as well. The polyester fabric’s quality is one possible problem. The brightness and longevity of the print can be greatly impacted by the quality of the polyester fabric, as not all polyester fabrics are made equal. The susceptibility of polyester to heat is still another possible problem. The cloth may burn or melt if the heat press settings are not set correctly, destroying the hat. As a result, throughout the sublimation process, it’s imperative to utilize premium polyester caps and to closely watch the heat press settings.

How does the quality of sublimation materials affect the final product?

The ultimate result of the sublimation process is largely dependent on the caliber of the sublimation materials. While low-quality materials may result in dull, fuzzy images, high-quality sublimation ink and paper can generate brilliant, clear prints. In a similar vein, the vibrancy and longevity of the print can be greatly impacted by the quality of the polyester fabric. Thus, making an investment in premium sublimation materials is essential to getting the best possible results while sublimating hats.

How can one start a business in hat sublimation?

Hat sublimation involves significant planning, as well as financial commitment, to get started. Purchasing the required tools and supplies, such as a heat press, polyester headwear, sublimation ink, and sublimation paper, is the first stage in the process. It’s crucial to understand the sublimation process and to put the method into practice. Once the fundamentals are understood, one can begin designing and selling personalized sublimated headwear to prospective clients. With custom clothing becoming more and more fashionable, hat sublimation can be a profitable company.

What are the initial investments for a sublimation business?

The price of the supplies and equipment is one of the startup costs for a sublimation company. The main tools required are a heat press, sublimation paper, ink, and a sublimation printer. Furthermore, hats made of polyester would need to be purchased for sublimation. The equipment’s features and quality can affect how much it costs. The cost of the design program, advertising, and operational charges are additional possible expenses. For the firm to be viable, these early investments must be properly planned for and budgeted for.

What are the current trends in the sublimation industry?

The sublimation business is always changing, with new trends appearing on a regular basis. Custom-made hats are becoming increasingly popular, and clients are looking for something different. There is an increasing need for sustainable materials and processes, which is driving the adoption of eco-friendly methods. Another trend is technological advancements, with new, more effective heat presses and sublimation printers being created. Keeping up with these developments can help a sublimation company remain competitive and meet the evolving expectations of its clientele.

Where can one find sublimation guides and tutorials for beginners?

There are several of materials accessible to study the fundamentals of sublimation for people who are new to the field. There are a ton of tutorials and guides available online on sites like YouTube, covering everything from equipment setup and troubleshooting to the sublimation process. Comprehensive tutorials and tips for beginners are available on websites such as CreativeFabrica.com and Sepsgraphics.com. Furthermore, more seasoned sublimation fans can provide helpful guidance and support in forums and online communities. Hat sublimation is an art that anyone can learn if they have the proper tools and are willing to put in the effort.