Sublimation printing allows the creation of bright, long-lasting designs that are printed on a variety of fabrics. This method characteristically creates eye-catching designs that last for a long time.

Defining the sublimation process in printing, it is worth noting that it is a unique technology that creates durable, perfect designs on polyester textiles and more. The process requires a thermal press, transfer paper, sublimation ink and a sublimation printer. The solid dye molecules become a gas under heat and pressure, and the gas penetrates the fabric or coated substance. Compared to other printing techniques, this produces a print that is integrated into the structure of the fabric, increasing its durability. Because of its customizability and high quality prints, sublimation printing is widely used in a wide variety of applications, such as textile and garment decoration, ceramic and mug printing, and printing on T-shirts and vinyl.

- Sublimation printing uses heat to transition dye from a solid to a gas, creating vibrant, durable prints.

- The process requires a dye-sublimation printer, sublimation ink, transfer paper, and a heat press.

- The prints are part of the fabric structure, making them more resilient than other printing methods.

- Sublimation printing is widely used in various applications due to its versatility and the quality of prints it produces.

| Printing Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Sublimation Printing | Uses heat to transform solid dye into gas, which then permeates the material to create the print. | Produces vibrant, full-color prints that are embedded into the material, resulting in a more durable and fade-resistant product. | Requires specific materials and equipment, and is more cost-effective for small to medium-sized print runs. |

| Screen Printing | Involves the direct application of ink onto the material’s surface. | Can be used on a variety of materials and is cost-effective for large print runs. | Prints may fade over time as the ink remains on the surface. |

| Inkjet Printing | Uses liquid ink to create prints, which is sprayed onto the material through tiny nozzles. | Can produce high-quality, detailed prints and is suitable for small print runs. | Prints may fade or smudge over time, especially if exposed to water or humidity. |

| Direct-to-Garment Printing | Uses a special printer to apply ink directly onto the fabric. | Can produce high-quality, detailed prints and allows for a lot of color variation. | Prints may fade over time and the process can be slow for large print runs. |

| Large Format Printing | Uses a large printer to create large-scale prints for banners, posters, and other large displays. | Can produce large, high-quality prints and is suitable for large print runs. | Can be expensive and is not suitable for small print runs. |

A comparison of the various printing techniques, such as sublimation, screen, inkjet, direct-to-garment, and big format printing, is given in this table. It lists each method’s benefits, drawbacks, and description.

What are the fundamentals of sublimation printing?

The groundbreaking process of sublimation printing is based on the scientific idea of sublimation, which is the process by which a material skips the liquid phase and instead changes from a solid to a gas. This procedure is essential to the dye-sublimation process, which turns solid dye particles into gas by applying pressure and heat. The polyester fabric or coated material is subsequently penetrated by the gas, producing a vivid, long-lasting print. Because the dye is integrated into the fabric structure rather than only applied on top, as is the case with conventional printing techniques, the print is more resilient. Because of this special feature, sublimation printing is the method of choice for producing high-quality, long-lasting graphics on polyester textiles.

What is the role of heat transfer in sublimation printing?

An essential component of sublimation printing is heat transfer. Without going through a liquid phase, the catalyst is what moves the dye from a solid to a gaseous state. The dye sublimates and penetrates the substance or cloth when heat is applied. The dye becomes embedded in the material and returns to its solid state after the heat source is withdrawn. This heat-induced change produces a pattern that is perfect for athletic and promotional products since it resists fading and wear even after several washings.

How does a dye-sublimation printer function?

The process of using a dye-sublimation printer involves putting dye in the form of a gas onto transfer paper. The printer heats the dye with a heating element, which causes the dye to sublimate. The transfer paper is then placed onto the material to be printed once the gaseous dye has penetrated it. The design is embedded in the material when the dye returns to a solid state due to the heat generated by the press. Through this technique, the design and material are seamlessly combined to create a print that is both bright and long-lasting.

Think about Epson EcoTank models when selecting a printer for sublimation printing. They employ refillable ink tanks rather than cartridges, which may end up being more economical over time, and are made for large-volume printing.

What is the difference between digital and sublimation printing?

Sublimation printing and digital printing are two separate techniques with different uses and outcomes. Digital printing applies ink directly to the surface of the substrate; it is frequently used for printing on paper and cardstock. Sublimation printing, on the other hand, uses heat to change a solid dye into a gas that seeps through the substrate to produce the print. The longevity and color brilliance of the prints are the primary differences. Digital prints may fade over time because the ink is still on the surface, while sublimation prints are more brilliant and durable since the dye becomes a part of the material.

What materials and equipment are needed for sublimation printing?

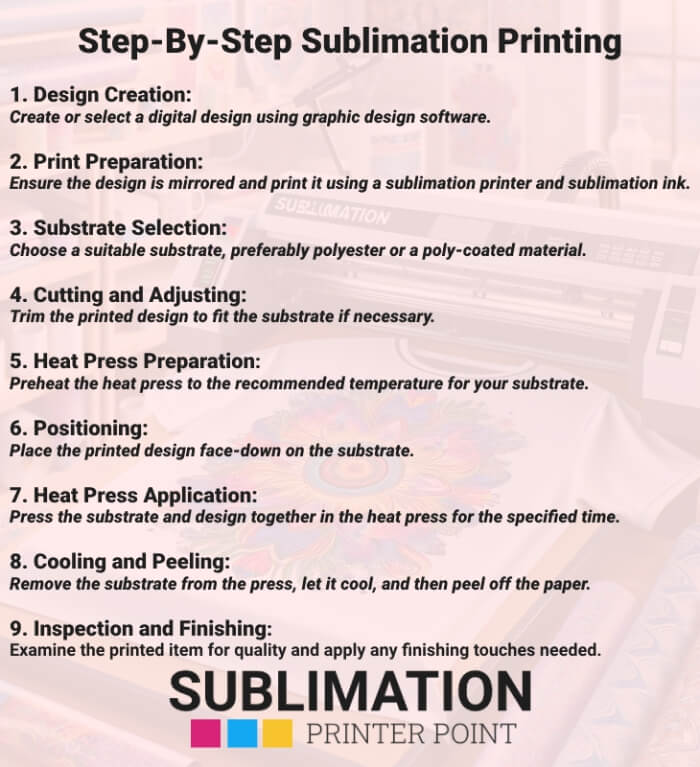

To get the desired results, sublimation printing needs certain supplies and tools. A heat press, transfer paper, sublimation ink, and a dye-sublimation printer are the necessary supplies. Another important factor is the substrate to be printed on, which is usually polyester or a polyester-coated substrate. Every part is essential to the process and adds to the durability and beauty of the finished print.

Why is polyester fabric often used in sublimation printing?

Because of its special qualities, polyester cloth is a popular option for sublimation printing. Polyester’s synthetic fibers are heat-resistant, which makes it perfect for the heat-intensive sublimation process. Furthermore, the material becomes permeable with the gaseous dye due to the fibers opening up when heated. The fibers shut when the fabric cools, enclosing the dye. In contrast to conventional printing techniques where the pattern only appears on the surface, this produces a vivid, fade-resistant print that is integrated into the fabric.

What is the purpose of transfer paper in the process?

In sublimation printing, transfer paper is the medium that transfers the design from the printer to the material. A dye-sublimation printer is used to print the design onto the transfer paper in the beginning. After that, the material is covered with the paper with the design on it, and heat is applied. The paper’s dye sublimates in the heat, permeating the substance and transferring the design. For a print transfer to be successful and accurate, the transfer paper plays a critical role.

Cricut Infusible Ink is a great option for sublimation projects for do-it-yourself enthusiasts. This tool is a fantastic choice for home use because it enables you to create vivid, fade-resistant graphics without the need for a typical heat press.

How does a heat press machine contribute to the process?

An essential part of the sublimation printing process is the heat press machine. It supplies the pressure and heat required to enable the dye’s sublimation. The heat from the machine converts the dye from a solid to a gas as it presses the transfer paper into the material. The design is then embedded in the material by the gaseous dye. Since heat is what causes the color to change, the sublimation process would not be feasible without the heat press machine.

What are the applications of sublimation printing?

Because of its adaptability and the high quality of the prints it generates, sublimation printing has many uses. The options are endless, ranging from vinyl and t-shirt printing to ceramic and mug printing to textile and clothing embellishment. Because of their strength and color vibrancy, sublimation prints are perfect for both personal and business use, providing a high-quality, long-lasting solution for a range of printing requirements.

How is sublimation printing used in textile and garment decoration?

Because sublimation printing creates vivid, long-lasting prints, it is widely utilized in textile and clothing embellishment. It enables the production of complex patterns with a broad color palette that are subsequently incorporated into the fabric to produce a print that is resistant to fading and wear. This makes it the perfect option for products where quality and durability are crucial, like athletics, promotional clothing, and fashion apparel.

What role does sublimation printing play in ceramic and mug printing?

Sublimation printing is essential when it comes to printing on ceramics and mugs. Custom and personalized graphics can be made on ceramic products like plates and mugs using this technology. The process’s high heat guarantees that the print is permanently incorporated into the coating of the ceramic, producing a product that is both dishwasher-safe and long-lasting. Because of this, sublimation printing is a well-liked option for producing branded presents and promotional goods.

Why is sublimation printing popular in t-shirt and vinyl printing?

The reason sublimation printing is so popular for printing on t-shirts and vinyl is that it can create prints that are both durable and of excellent quality. Vibrant, full-color designs that are incorporated into the vinyl or fabric rather than just sitting on the surface can be produced thanks to this method. As a result, even after numerous washes or uses, the print will not fade or crack. Furthermore, sublimation printing is a recommended option for vinyl and t-shirt printing due to its ease of creating intricate and sophisticated designs.

How does sublimation printing compare to other print technologies?

Because of its distinct method and superior print quality, sublimation printing is distinguished from other print technologies. Sublimation printing, as opposed to screen and inkjet printing, makes it possible to create vivid, full-color prints that are incorporated into the material, making the finished product more resilient to fading. Sublimation provides more freedom in terms of the materials that may be printed on and the intricacy of the designs as compared to direct-to-garment printing. For small to medium-sized print runs, sublimation printing is a more affordable option than big format printing.

How does sublimation printing differ from screen and inkjet printing?

The method and product of sublimation printing are very different from those of screen and inkjet printing. Sublimation printing uses heat to change solid dye into gas, which then permeates the material to make the print, as opposed to screen and inkjet printing, which apply ink directly onto the material’s surface. Unlike screen and inkjet printing, where the ink stays on the surface and may fade over time, this produces a print that is more brilliant and long-lasting because the dye becomes a part of the material.

What are the advantages of sublimation over direct-to-garment printing?

Comparing sublimation printing to direct-to-garment (DTG) printing reveals a number of advantages. First off, because the dye is integrated into the cloth, sublimation prints are stronger and less likely to fade. DTG prints, on the other hand, could fade over time because the ink is still on the surface. Second, DTG printing might not be able to produce intricate, full-color graphics with a broad color gamut like sublimation printing can. Last but not least, sublimation printing is more affordable for small to medium-sized print runs, which makes it a more sensible choice for a lot of companies and people.

Why might one choose sublimation printing over large format printing?

For a variety of reasons, sublimation printing may be preferred over large format printing. First of all, sublimation printing makes it possible to create vivid, full-color designs that are infused into the material, making the finished product more resilient to fading. Large format printing, on the other hand, might not provide the same degree of robustness and color brightness. Second, big format printing might be more appropriate for tasks with a lot of material, while sublimation printing is more economical for small to medium-sized print runs. Finally, sublimation printing is a more versatile alternative due to its flexibility in terms of the materials that may be printed on and the intricacy of the designs.

What are the design and color management considerations in sublimation printing?

In sublimation printing, design and color management are essential factors to take into account. The medium to be printed on and the intended outcome must be considered when creating the design. Color management is also vital because the print must precisely reproduce the colors in the design. This calls for using premium sublimation inks and meticulous printer calibration. When it comes to sublimation printing, these factors are crucial in producing prints of superior quality.

How does graphic design impact the sublimation printing process?

An important part of the sublimation printing process is graphic design. The final product that is printed onto the material is the design, thus it must be properly created to guarantee a high-quality print. This entails designing a layout that works with the material and the printing process, considering aspects like color harmony, intricacy of the layout, and the intended outcome. An effective design can greatly improve the finished product by increasing its impact and attractiveness.

What role does color management play in achieving high-quality prints?

In sublimation printing, color management is essential to producing prints of excellent quality. It entails making certain that the print faithfully captures the colors in the design. This necessitates using premium sublimation inks and meticulous printer calibration. Inadequate color management could lead to a print where the colors don’t match the design, which would produce a mediocre output. Color control is therefore an important step in the sublimation printing process that shouldn’t be skipped.

How does print on demand influence the design choices in sublimation printing?

Sublimation printing design decisions are greatly influenced by print on demand. Custom designs can be created as and when needed using print on demand, as the name implies. Because it enables the creation of distinctive, customized designs for every print, this provides a high degree of freedom. It also necessitates carefully weighing the design components because each one must work with sublimation printing and be appropriate for the material that will be printed on. As a result, print on demand has the potential to significantly expand the applications for sublimation printing, but it also necessitates careful planning and design.